Making a donut chuck

Donut chucks are simple, cheap fixtures for finishing off the feet of bowls. Yes, there's no need to glue green felt on the bottom to hide those unsightly screw holes, or to have a foot that looks like a tenon (because it was).

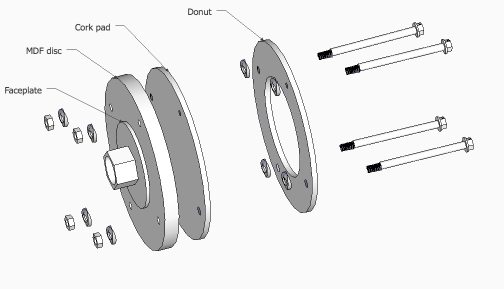

The SketchUp model below shows the parts, which must be adapted to fit your lathe. Make sure the discs are smaller than the maximum capacity of your lathe.

I start with an inexpensive, dedicated faceplate for my 1-1/4—8 lathe spindle. I get these from Bill Noble, a half-dozen at a time. They're not pretty and their faces aren't trued, but for dedicated applications that makes no difference. The price is right.

I screw an MDF disc to the faceplate and turn its face true, then glue a 1/8" cork disc to it. (hardware stores sell sheet cork by the square foot). I next cut a donut disc of 1/4–3/8" MDF, clamp it to the previous assembly, and drill 1/4" holes through both discs plus the cork. Now everything will line up. At the same time, I put registration marks on the donut, showing which side faces the tailstock and how it matches up with the main MDF disc.

I mount the donut disc to the main assembly with short 1/4" bolts and nuts, using a few washers as spacers to raise the donut away from the cork. Then I put the assembly on the lathe and, at low speed, turn the hole in the center of the donut to fit my bowl. I bevel the inside edge so it won't mark my bowls.

That's it. Replace the short bolts with longer ones, center your bowl with the rim facing the cork, and gently tighten the bolts until the donut holds the bowl firmly. Check that the donut has drawn up evenly all the way around.

Now you can turn that mounting tenon into a graceful foot, with a little decoration in the bottom.